The Best Solution For Energy Saving And Reducing CO2 Emission

The Best Solution For Energy Saving And Reducing CO2 Emission

Tel: +86-532-85717690/85717352/85832089

Tel: +86-532-85717690/85717352/85832089 E-mail: wam@wamcn.net

E-mail: wam@wamcn.net

If you need to insulate a home or commercial setup, you can ruminate on several insulating materials that help maintain the heat and keep the insides cozy and warm.

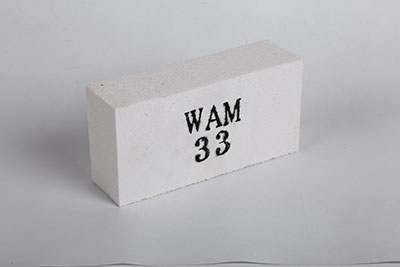

Insulation bricks are used in lining kilns as they are light in weight and also inhibit the abrasion of kilns.

They are low in density, thereby making them the ideal material to be used for lining kilns, ovens, furnaces, etc.

Insulation bricks used in refractories are called Refractory bricks. They are one of the most regular insulation bricks that are widely used in high-temperature environments such as kilns, furnaces, and more.

Several insulating brick manufacturers proffer a range of refractory bricks in various shapes, sizes, and styles.

Contrasting to other bricks, insulated bricks do not easily heat up and can also weather high temperatures with no hassles.

They save heat energy gotten from chimneys, furnaces, kilns, etc., which in line helps save money or cost.

Owing to their heat resistant features and low cost, insulated bricks are desired in various industries such as ceramic, petrochemical, aluminum, chemical, glass, steel, and more.

End users can also get insulated bricks customized to their specifications or needs.

If you are looking forward to buying insulating bricks, ensure it is from a reputed manufacturer who can supply according to your requirements.

Types of Insulating Bricks

There are two types of insulation bricks; the one used at lower temperatures and the one used for higher temperatures.

1. Lower temperature insulation bricks

Low-temperature insulation bricks are manufactured using raw diatomite, mica, and granules of vermiculite.

During the manufacturing process, thick voids are bequeathed in the bricks, thereby making the insulation appropriate.

2. Higher temperature insulation bricks

This type of bricks is manufactured using raw kyanite and granules of calcined clay. Additionally, combustible materials are also used.

Kyanite has an exceptional expansion property, and as it expands, the insulating brick becomes absorbent, hence making the insulation proper.

Uses of Insulation Bricks

Insulation bricks are used in gas burners, chimneys, electric systems, small wood stoves, kiln linings and external insulation. They are mainly used as backup linings.

Insulation bricks possess low thermal conductivity as they endure a temperature of up to 1760oC.

Insulated bricks cannot withstand much heat compared to firebricks; more reason they are used for under-floor bricks, lining, and outer walls.

They are as well used in boilers but not in wood-fired ovens as they do not sop up the heat in any way.

They are extensively used in commercial functions such as production that necessitates mechanical, chemical, and thermal processes.

In situations where the transmitted heat is intense, firebricks are used in place of insulation bricks.

Also, insulated bricks are used in shielding surfaces from intense heat, as in the electric plants.

Reasons for their popularity include energy efficiency, fire prevention, lightweight, durability, and being economical.

In case you are deeming to buy insulating bricks that can be customized to your specified needs, endeavour to patronize a professional manufacturer.

Kindly contact us today for a guaranteed top-notch product.