The Best Solution For Energy Saving And Reducing CO2 Emission

The Best Solution For Energy Saving And Reducing CO2 Emission

Tel: +86-532-85717690/85717352/85832089

Tel: +86-532-85717690/85717352/85832089 E-mail: wam@wamcn.net

E-mail: wam@wamcn.net

More porosity brings excellent insulation effect,energy saving.

High crushing strength under thermal state, volume stability.

Little thermal storage when absorb more heat, energy saving effect is obvious.

Low content of iron, alkaline and metal impurities.

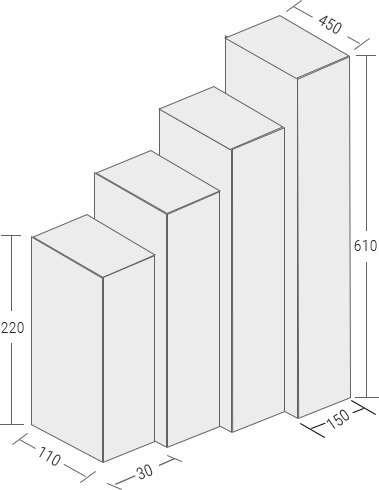

Precise brick size by machining, cutting and grinding special shapes, expediting bricklaying.

| WAM A-Series | |||||||

|---|---|---|---|---|---|---|---|

| A-1 | A-2 | A-3 | A-4 | A-5 | A-6 | A-7 | |

| Temp.(°C)Reheating Shrinkage less than 2% | 900 | 1000 | 1100 | 1200 | 1300 | 1400 | 1500 |

| Bulk Density(g/cm³) | 0.50 | 0.50 | 0.50 | 0.55 | 0.60 | 0.70 | 0.75 |

| Cold Crushing Strength (kg/cm²) | 5 | 5 | 5 | 8 | 8 | 10 | 10 |

| Thermal Conductivityat 350°C(W/m.k) | 0.13 | 0.14 | 0.15 | 0.16 | 0.17 | 0.20 | 0.22 |

| WAM B-Series | |||||||

|---|---|---|---|---|---|---|---|

| B-1 | B-2 | B-3 | B-4 | B-5 | B-6 | B-7 | |

| Temp.(°C)Reheating Shrinkage less than 2% | 900 | 1000 | 1100 | 1200 | 1300 | 1400 | 1500 |

| Bulk Density(g/cm³) | 0.70 | 0.70 | 0.75 | 0.80 | 0.80 | 0.90 | 1.00 |

| Cold Crushing Strength (kg/cm²) | 25 | 25 | 25 | 25 | 25 | 30 | 30 |

| Thermal Conductivityat 350°C(W/m.k) | 0.17 | 0.18 | 0.20 | 0.22 | 0.23 | 0.27 | 0.32 |

No longer are there design limitations caused by traditional standard brick shapes and sizes. The nominal cost of customized sizes is more than offset by the elimination of many mortar joints and significant labor savings.

IOS14001

IOS14001ISO14001:2015 quality management.

ISO9001:2015 quality management

system certification.