The Best Solution For Energy Saving And Reducing CO2 Emission

The Best Solution For Energy Saving And Reducing CO2 Emission

Tel: +86-532-85717690/85717352/85832089

Tel: +86-532-85717690/85717352/85832089 E-mail: wam@wamcn.net

E-mail: wam@wamcn.net

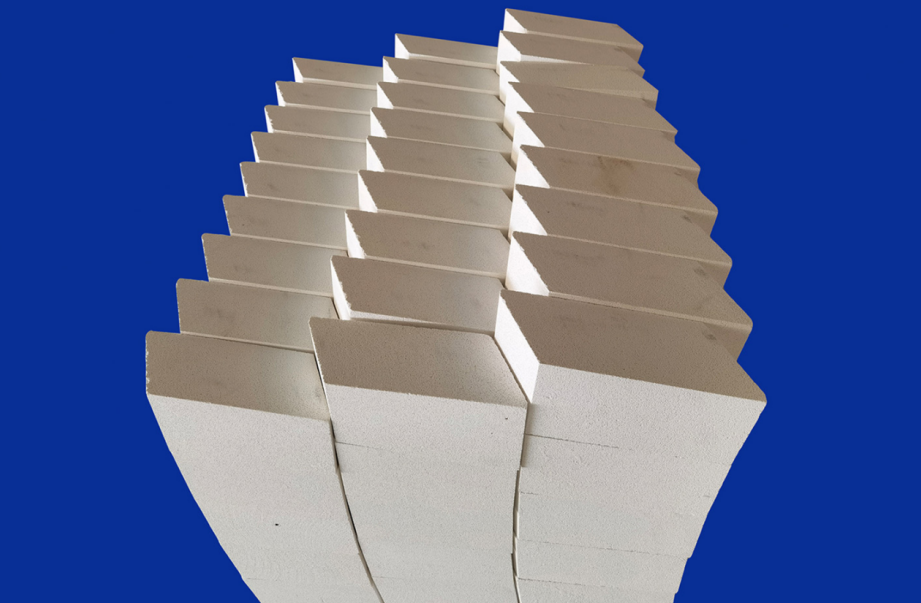

Insulating fire bricks which you can refer to as refractory bricks are designed to endure extremely high temperatures.

A combined attribute of chemical substances like silica and alumina provides fireclay with the special ability to endure high temperatures. Additionally, it is used to line fireplaces, kilns, furnaces, and fireboxes.

Scientifically, insulating fire bricks withstand temperatures as high as 3,500 degrees Fahrenheit. Also, one of the benefits of having an insulating brick is that it is adaptable to low or high temperatures.

Insulating fire bricks are usually known for their ability to conserve energy. Furthermore, weightless Insulating blocks are highly efficient bricks for the ecosystem. They can be easily dissected, cut, or destroyed.

This is an insulating fire brick made of high alumina and powder. It is usually mixed with other raw materials and then cooked at 1750 degrees Fahrenheit.

In addition, High alumina brick is a type of brick that saves factory production costs and energy consumption, reduces the weight of the kiln, and increases efficiency of the kiln.

High alumina brick is used in industries characterized by high-temperature linings. Also, it can be found in petrochemical industries, metallurgical industries, and other industries with high-temperature kilns.

These types of bricks are made of lightweight mullite raw materials that consist of high-quality refractory powder. The brick product is good for high temperatures and it is resistant to erosion. It is used in the iron and steel industries. Moreover, it can be used for forming glass kilns to avoid the erosion of glass melt.

This special type of refractory brick is made of calcined andalusite. This raw material is essential in saving energy and costs, reducing fuel usage, and saving at least 40% of the number of raw materials consumed.

Additionally, the material is used for high-temperature aluminosilicate insulators, making kiln equipment, and sand mold fabrics. It is used in the hot stove, reheating, etc.

This is an insulating fire brick marked by resistance to acid or any metal or glass liquids that may cause damage.

Typically, the brick is utilized in hot blast stoves, sliding water heaters, glass refining furnaces melting furnaces, blast furnaces Petrochemical furnaces, etc. Corundum brick is essential for the making of steel, electronics, fertilizer, petrochemicals, etc.

There are five steps in manufacturing insulating bricks.

1. The first step involves filling and compressing the selected raw materials inside a mold.

2. The second step involves placing the mold at a temperature of 10-20 degrees Celsius for 24 hours to remove the mold.

3. The third step involves putting the bricks in an environment where rain or moisture will not damage them for 14-16 days.

4. The fourth step involves using the brick as a kiln wall

5. The fifth step involves drying the mold for 80-110 hours under a certain degree of temperature. After drying, you perform light burning and natural cooling.

Insulating fire bricks consist of ceramic materials designed for several uses, including fireboxes, kilns, melters, and different types of furnaces. Some of the furnaces you can use it for include gas furnaces, oil furnaces, natural furnaces, and electric furnaces.

1. The high insulating value of fire bricks increases efficiency and reduces the costs of production.

2. Insulating fire bricks are known for their high compressive strength.

3. Insulating fire bricks are used in a lot of furnaces because of their high purity and quality which enhances performance.

4. Fire bricks are accurately cut into different suitable shapes and sizes which make them stronger and give them a tighter refractory lining. This is usually done to reduce the loss of heat through the joints.

Do you need high-performance insulating fire bricks that can withstand a wide range of temperatures?

Don’t worry, we got you covered. We are a leading manufacturer and supplier of insulating bricks with over 12 years of experience processing and manufacturing various grades of insulating bricks.

Kindly click here to get your durable insulating brick.