The Best Solution For Energy Saving And Reducing CO2 Emission

The Best Solution For Energy Saving And Reducing CO2 Emission

Tel: +86-532-85717690/85717352/85832089

Tel: +86-532-85717690/85717352/85832089 E-mail: wam@wamcn.net

E-mail: wam@wamcn.net

The submerged arc furnace is utilized for metal oxide ore reduction smelting.

It is also used to extract metal from slag and melt pre-reduction furnace charge.

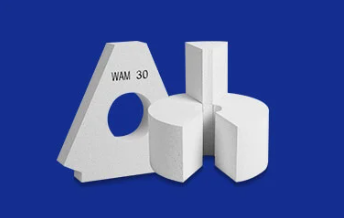

Insulating bricks are used to construct the furnace lining masonry, also known as refractory material masonry, for the submerged arc furnace.

In order to prevent the molten pool of a submerged arc furnace from being eroded and physically washed by the furnace charge, ever-rising furnace gas, molten iron, and high-temperature slag, it is crucial to choose particular properties for the making of refractory materials.

Insulating bricks are the primary refractory material used in the brickwork of the submerged arc furnace, with refractory castable serving as a complement. The following is the material selection:

When creating insulating bricks, carbon is an important material to consider. Crushed coke and anthracite are used to make carbon.

These bricks have great fire tolerance, high resistance to thermal shock, and substantial compressive strength. They also have good chemical stability, particularly dimensional stability and slag resistance.

But the oxidation rate will speed up as the temperature rises since it is easily oxidizes at high temperatures.

As a result, carbon materials cannot come into contact with air, steam, or any other gases at elevated temperatures. Carbon materials have great heat conductance but low thermal insulating capacity.

Insulating bricks made of carbon can be utilized as lining materials in submerged arc furnaces for all types of metals that are resistant to carburization.

Magnesium oxide is the primary component of magnesia brick. It has high refractoriness at temperatures over 2273k and excellent alkali tolerance; although, the load softening point is minimal, and thermal shock resistance is inadequate.

The majority of refining furnaces melt in an alkaline condition.

When looking for alkaline corrosion-resistant insulating materials, magnesia brick is a good choice.

Clay bricks are weak acid-refractory materials that may withstand acid slag erosion. insulating clay bricks, on the other hand, cannot be utilized at high temperatures.

Since the choice of refractories for submerged arc furnaces depends on the particular smelting conditions and smelting input materials. Therefore, alumina bricks have the potential to substitute clay bricks in a submerged arc furnace molten pool.

High alumina bricks offer greater benefits when it comes to overall efficiency. The most popular amorphous refractories are cold ramming slurry and high alumina cast-able.

It is advisable to take note of these refractory insulating bricks properties for optimal performance of submerged arc furnaces, and kilns.

1. Excellent refractoriness

2. High shape and volume stability when exposed to high temperatures

3. High-thermal strength

4. Good slag resistance

5. High chemical stability at high temperatures

6. They should have a robust, hard look.

7. impurity content is low

8. no structural flaws or cracks

Consider working with a refractory business that offers high-quality products as well as refractory services if you want the greatest insulating bricks solutions.

Therefore, if you're seeking high-performance insulating bricks, our team of refractory experts can help you locate the ideal insulating option for your application.

Please click here to get in touch with us, we would be excited to work with you.