The Best Solution For Energy Saving And Reducing CO2 Emission

The Best Solution For Energy Saving And Reducing CO2 Emission

Tel: +86-532-85717690/85717352/85832089

Tel: +86-532-85717690/85717352/85832089 E-mail: wam@wamcn.net

E-mail: wam@wamcn.net

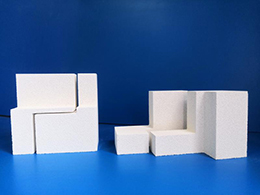

Lightweight fire brick generally refer to foam bricks. Normal indoor partition walls use this kind of brick because it does not increase the floor load, and the sound insulation effect is good. The heavy products are made of high-quality plate-like corundum and mullite as aggregates, with sillimanite composite as the matrix, and special additives and a small amount of rare earth oxides are mixed, after high-pressure molding and high-temperature firing. The material of ordinary light-weight heat-resistant refractory bricks are clay, high-alumina strength floating bead bricks, mullite and high-aluminum poly-light ball refractory bricks, and diatomite heat-resistant refractory bricks.

The advantages of lightweight fire brick are as follows:

1. Economic efficiency: it can reduce the cost of foundation, reduce the cross-section of the frame, ,save the reinforced concrete and significantly save the comprehensive cost of the building. Designed to use light bricks than solid clay bricks, the overall cost can be reduced by more than 5%.

2. Practicability: The use of lightweight bricks can increase the area of use. At the same time, due to the thermal insulation of aerated concrete, the thermal insulation effect is good. In hot summer, the indoor temperature would be 2-3°C lower than that of solid clay bricks. Use air conditioning to reduce power consumption.

3. Workability: lightweight fire bricks have good machinability, and the construction is convenient and simple. Due to the large size and light weight, it can reduce labor intensity, improve construction efficiency, and shorten construction period.

Compared to heavy fire brick, the difference between light fire brick and heavy fire brick is as follows:

1. The thermal conductivity of lightweight fire brick is generally 0.2-0.4 (average temperature 350±25℃) w/mk, while the heat conduction of heavy brick The coefficient is above 1.0 (average temperature 350±25℃) w/mk, which can be concluded that the thermal insulation performance of light bricks is much better than that of heavy bricks.

2. The refractoriness of lightweight fire brick is generally below 1400 degrees, while the refractoriness of heavy bricks is above 1400 degrees.

3. Lightweight fire bricks are generally light insulation materials, the density is generally 0.8-1.0g/cm3 and the density of heavy bricks are basically above 2.0g/cm3.

Qingdao Western Coast Advanced Materials Co., Ltd. (WAM) established in 2007 and located in the beautiful coastal city – Qingdao, is a leading manufacturer of wide range of mullite insulating fire bricksworldwide. WAM insulating products are widely applied in middle and high temperature furnaces in the field of Metallurgy, Aluminum, Petrochemical, Ceramics, Power and Glass industry, etc. If you encounter any problems about anything, please feel free to send us inquiry and we will do our best to assist you to solve the issue.