The Best Solution For Energy Saving And Reducing CO2 Emission

The Best Solution For Energy Saving And Reducing CO2 Emission

Tel: +86-532-85717690/85717352/85832089

Tel: +86-532-85717690/85717352/85832089 E-mail: wam@wamcn.net

E-mail: wam@wamcn.net

What is Insulating fire bricks?

Insulating fire bricks (IFB) belong to the group of thermal insulation bricks. IFB are shaped refractory products with an application temperature of greater 800°C and a total porosity greater than 45%. Insulating fire bricks are classified according to ASTM C155, EN 1094-2, ISO 2245 or JIS R2611.

Insulating fire bricks are mainly used in shuttle kilns, tunnel kilns or lab kilns. Further fields of application include heat treatment furnaces as well as petrochemical plants such as reformers/cracker furnaces or combustion chamber linings.

How is the insulating refractory brick made?

The main production processes of insulated refractory bricks are: raw material selection, powder preparation (crushing, crushing, screening), ingredients, mixing, pipe forming, drying, sintering, inspection and packaging.

The main steps are as follows:

(1) Filling: Filling material into the die by vibration and compaction.

(2) Demoulding: After filling the mold, the mold is placed in a temperature environment of 10-20 degrees Celsius for 24 hours before demoulding.

(3) Station: Bricks supported by mattresses are placed in indoor rain-proof and moisture-proof environment for 14 to 16 days.

(4) Kiln structure: brick wall is used as brick blank as kiln wall, steel lining refractory fiber blanket as top cover, covering the days of 100-40 mm in diameter. If one end of kiln wall is 1000, it is equipped with a kitchen, and the other end is connected with the chimney outlet.

(5) Drying:

1. Open the heavenly eye, raise the temperature in the kiln to a certain temperature with a certain heating rate, close the heavenly eye and keep the temperature 80-110 hours.

2. Open the heavenly eye, raise the temperature in the kiln to a certain temperature with a certain heating rate, close the heavenly eye and keep the temperature between 80 and 110 hours.

3. Reduce the temperature in the kiln to below 100 degrees Celsius and complete the drying stage.

(6)Light burning.

(7) Natural cooling.

How to use light weight fire bricks insulation

Use of light weight fire brick insulation is broad, mainly in industrial and hobby kilns heated up with either electric spiral elements or gas burners, furnaces, both for hot face lining or outer back-up heat insulation.

About us

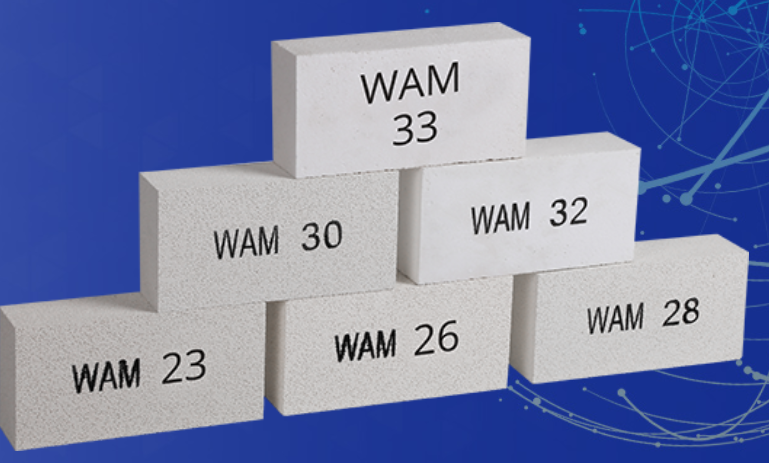

Qingdao Western Coast Advanced Materials Co., Ltd. (WAM) established in 2007 and located in the beautiful coastal city – Qingdao, is a leading manufacturer of wide range of mullite insulating bricks worldwide. WAM insulating products are widely applied in middle and high temperature furnaces in the field of Metallurgy, Aluminum, Petrochemical, Ceramics, Power and Glass industry, etc.

The production is strictly manufactured according to ASTM, JIS and DIN standard, and was certified by ISO9001:2015 quality management system and ISO14001:2015 environmental management system. The production capacity is 8,000,000 pieces of standard bricks per year.

WAM has our own testing laboratory with full set of testing equipments, including Multi-Element Chemical Analyzer, Thermal Conductometer , Permanent Liner Change Experimental Furnace, Cold Crushing Strength Tester & Modulus of Rupture Tester, Flame Photometer, which is the strong assurance to the quality.