The Best Solution For Energy Saving And Reducing CO2 Emission

The Best Solution For Energy Saving And Reducing CO2 Emission

Tel: +86-532-85717690/85717352/85832089

Tel: +86-532-85717690/85717352/85832089 E-mail: wam@wamcn.net

E-mail: wam@wamcn.net

Insulating fire bricks (IFB) are a special type of bricks that can withstand extreme temperatures while acting as insulations. Basically, the IFB are used to line kilns and furnaces, fireboxes and fireplaces.

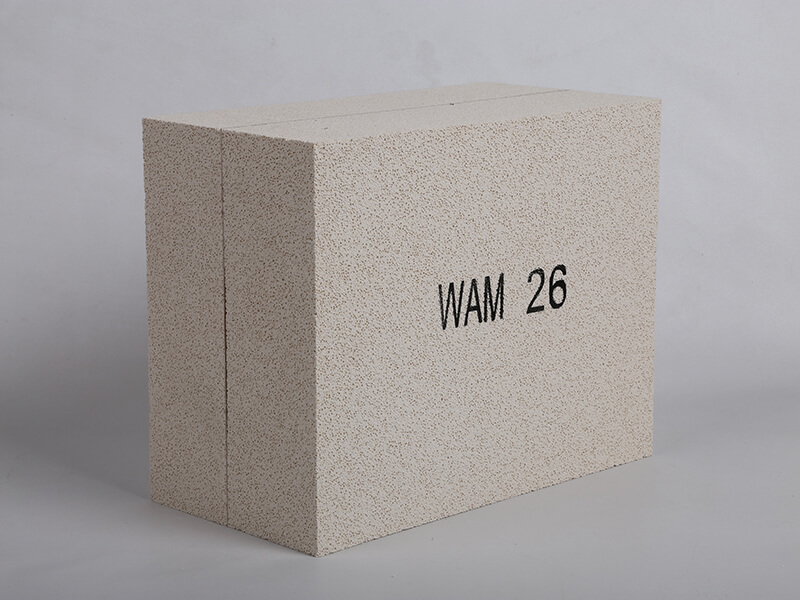

High-temperature insulation products remain a vital component in many installations industrialists. The Western Coast insulating brick maintains a unique position within the available high-temperature insulation products, as it offers a unique combination of insulating properties with load-carrying capacity.

The Western Coast insulating bricks are particularly suitable for applications above 1000oC, where the thermal conductivity is as low as ceramic fiber products (in some cases even less), but with structural integrity capable of dealing with erosive and abrasive environments.

In this article, we focus on the advantages of the western coast insulating brick.

Let’s get started!

Product description:

The insulating bricks are composed of various compounds - mainly Silicon Oxide (SiO2) and Alumina (Al2O3) - combined in different proportions as the case may be, compressed under vacuum and sintered under high temperatures.

Features

Low thermal conductivity (does not retain heat)

High resistance to compression

High purity

Extremely low CaO content for atmospheres rich in hydrogen sulfides and chlorides.

High thermal resistance, can work with direct fire

High resistance to thermal shock

Easy to cut and adjust to size

Advantages of using the Western Coast insulating brick arrangements:

Being highly resistant to heat flow, the unique WAM products give the traditional refractory function an extra advantage.

They are light and store much less heat. Its lightness makes installation and stacking faster. In addition, the required supporting structure, either steel or foundation, can be lighter and therefore more economical.

Weight can be reduced by 80% compared to dense refractory bricks.

They have the highest compressive strength of all insulating refractories.

They are structurally stable at high temperatures.

The western Coast insulating bricks are dimensionally compatible with Dense bricks adding firmness to construction.

Being machined to give them their finish, they have more precise tolerances than dense fired clay bricks. This results in more compact constructions with less heat loss through the joints and faster installation.

Using 3in insulating bricks reduces installation times and 17% fewer joints are used in installation than 2.5in

Easy to machine to fit.

Other typical Applications:

Coating of various types of furnaces in the metallurgical, petrochemical, ceramic and construction materials industries: combustion chambers of furnaces for thermal treatment, ceramic curing, maintenance, tunnel, etc.

They can be placed as a work face in contact with direct fire or as a backing behind concrete or refractory brick.

In order for companies to ensure that they achieve the most efficient energy consumption possible, it is important that designers of industrial installations understand that not all insulating bricks are the same.

There is a wide range of insulating bricks for sale. However, when selecting insulating bricks for a specific application, it is important to know how the different combinations of performance parameters are the most suitable for the existing working conditions. It is also important to understand that the most efficient thermal installation is only achieved with the combination of the products.