The Best Solution For Energy Saving And Reducing CO2 Emission

The Best Solution For Energy Saving And Reducing CO2 Emission

Tel: +86-532-85717690/85717352/85832089

Tel: +86-532-85717690/85717352/85832089 E-mail: wam@wamcn.net

E-mail: wam@wamcn.net

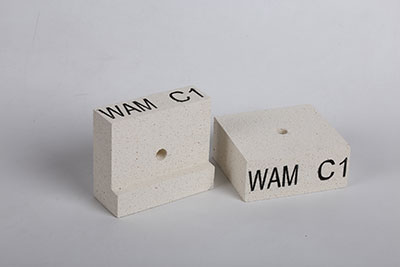

Diatomite insulation brick is a type of refractory brick that is made of natural porous diatomite, clay, and combustible materials.

Diatomite insulation brick has micropores, low bulk density, excellent energy-saving effect, low thermal conductivity, good insulation performance, and more.

Aside from having a good sound absorption effect, diatomite insulation brick can also reduce fuel consumption as well as reducing heating time.

The operating temperature of diatomite insulation brick is between 900-1000oC and can only be used in the mid-temperature insulation layer.

The insulation performance of the diatomite insulation brick is due to its high porosity and loose structure, but are not suitable in areas where there is direct contact with metals and molten slags.

Diatomite insulation brick has low mechanical strength. It also has poor wear resistance, therefore, making it unfit in badly worn areas of application.

Advantages such as non-toxic, easy installation, and non-deformation make diatomite insulation brick the preferred choice for energy-saving equipment.

Diatomite insulation brick is used in different applications such as textiles, light, electricity, glass, cement, ceramics, etc.

Are you looking for the ideal insulation material? Do contact a trusted refractory brick manufacturer for a quality product.

The Manufacturing Process of Diatomite Insulation Brick

The manufacturing process is as follows:

o Raw Materials and Processing

The raw materials used for the production of diatomite insulation brick are diatomaceous earth, sawdust, scrap bricks, and pulverized fuel ash.

The diatomaceous earth has plasticity and the finer the particles, the better the plasticity.

To get better plasticity of diatomaceous earth as well as to remove some soluble salt which enhances chemical and physical properties, it has to be weathered before usage.

To get a good quality of diatomaceous earth, the processing needs to take different methods.

The diatomaceous earth could be ground to finer particles less than 1.5mm, or stirred into a small lump of clay by stirring blade or weathered to fragments.

The moisture content of sawdust should be less than 50% while particle size is less than 1mm.

For the pulverized fuel ash, the moisture content has to be less than 26%.

o Mixing and Batching

The raw materials are mixed in a kneading machine or mixer. Gases and hot water are added at a low temperature.

A quantity of clinger, as well as pulverized fuel ash, are introduced to reduce the cracking and shrinkage of the brick during sintering and drying.

o Forming

This stage requires hand moulding, extrusion moulding, and mechanical pressing moulding.

The purpose of the extrusion moulding is to extrude clay in the needed size with the help of the extrusion machine, then cut into the required length and thickness.

The purpose of the mechanical pressing moulding is to press the mud into needed shape with the use of a 150-300kn brick machine.

While the purpose of the hand moulding is to mould the brick by hand with the use of a wooden mould.

o Drying

Drying of the diatomite insulation brick is done with the use of a tunnel dryer or fire pit.

When using a tunnel dryer, the inlet temperature should be 40-50oC while the outlet should be about 150oC with sufficient airflow.

To avoid cracks, it is better to make use of the low-temperature slow drying; this is due to the high moisture content.

o Firing

The diatomite insulation bricks are stacked with the use of a pigsty stacking. The height of the stacking should not surpass 1.5m.

At low temperature – 200oC or less, water is being removed from the brick. temperature need not be increased rapidly.

Crystal water begins to remove at a temperature above 200oC while organic materials like sawdust begin to burn at about 500-600oC.

The temperature is finally being controlled at about 900oC, then the fired bricks are processed into final products.

In Need of Premium Refractory Brick?

In case you have been considering where to get a quality refractory brick that suits your need, kindly contact us for the best deals.