The Best Solution For Energy Saving And Reducing CO2 Emission

The Best Solution For Energy Saving And Reducing CO2 Emission

Tel: +86-532-85717690/85717352/85832089

Tel: +86-532-85717690/85717352/85832089 E-mail: wam@wamcn.net

E-mail: wam@wamcn.net

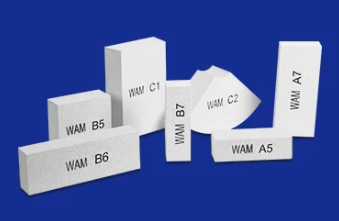

Refractory bricks are heat-resistant building materials that can also be called fire bricks. Made of refractory ceramic substance, they are used to line furnaces, fireboxes and kilns.

Generally composed to withstand high temperatures, refractory bricks include materials such as aluminium and silicon dioxide. These materials and the processes involved in manufacturing them help them maintain excessive heat without melting.

Refractory bricks are different from other bricks because of certain qualities that make them heat resistant. Applications which involve extreme thermal, mechanical and chemical stress involve the use of firebricks.

Here are some high resistant qualities that make the bricks unique in nature:

The high resistant qualities of refractory bricks are largely found in their composition. Chemical compositions used in making refractory bricks include silica, alumina, lime, clay, chrome iron ore and sandstone.

These major elements help determine the characteristics and quality of refractory bricks. Each type of fire brick is manufactured through a special combination of these chemicals.

Alumina and silica are known to be heat-resistant materials that are largely found in ordinary firebricks. With these chemical combinations, firebricks are able to resist a temperature of up to 1000 degrees.

This quality is the bricks' ability to resist high-temperature loads without melting or breaking apart. It is related to the load softening temperature or deformation temperature.

It is expected that the bricks can retain their form not only under high temperatures but under heavy weight as well. Tests are conducted on the bricks to measure the load pressure or capacity in high temperatures. It is very significant because it checks the temperature resistance of materials.

The bricks have the ability to resist sudden differences in temperature without being demolished. While other bricks may not resist sudden temperature change, fire bricks are known to stay strong in such situations.

This quality assures users of their safety in cases of thermal shock. This quality also helps make sure that the bricks last longer.

Fire bricks possess the quality of being able to withstand a very rapid temperature change. Where other bricks may be affected by the situation and split or crack, firebricks tend to retain their shape.

Rapid changes in temperature take place in cases such as oven use. In such cases, the fire bricks can be trusted to not sustain damage. They can withstand the tendency to crack and split off fragments when faced with a rapid change of temperature.

Fire bricks can increase in volume due to high temperatures. One quality they possess is being able to reverse to their normal sizes after such a situation.

Volume fluctuation and expansion is very normal in firebricks and is reversible. Reversible volume fluctuation prevents issues such as leaks, openings and cracks

Are you in need of Refractory bricks for high-temperature environments?

Refractory bricks are known for their insulating capabilities. They are known not only to resist high temperatures but to retain them as well.

Do you need fire bricks for your home or industries? You can get your refractory bricks for your high-temperature environments right here.