The Best Solution For Energy Saving And Reducing CO2 Emission

The Best Solution For Energy Saving And Reducing CO2 Emission

Tel: +86-532-85717690/85717352/85832089

Tel: +86-532-85717690/85717352/85832089 E-mail: wam@wamcn.net

E-mail: wam@wamcn.net

In today's competitive industrial landscape, maximizing efficiency and minimizing energy consumption are top priorities for businesses across various sectors. One key aspect of achieving these goals lies in thermal management, particularly in environments where high temperatures are prevalent. Customized Insulating Bricks emerge as indispensable solutions, offering tailored thermal insulation solutions to meet the diverse needs of industries.

At WAM, we understand the critical role that thermal insulation plays in optimizing processes and reducing energy costs. That's why we offer a comprehensive range of Customized Insulating Bricks, including customized fire bricks, customized refractory bricks, and insulating fire bricks, designed to address the unique thermal challenges faced by our customers.

Our Customized Insulating Bricks are engineered to provide superior thermal insulation properties, effectively minimizing heat transfer and ensuring energy efficiency in high-temperature environments. By tailoring our solutions to meet the specific requirements of each application, we empower businesses to achieve optimal thermal performance and enhance overall productivity.

The versatility of Customized Insulating Bricks makes them suitable for a wide range of industrial applications, including but not limited to:

Steel Manufacturing: In steelmaking processes, where extreme temperatures are common, Customized Insulating Bricks play a crucial role in lining furnaces, ladles, and other equipment, effectively retaining heat and improving process efficiency.

Glass Production: The glass manufacturing industry relies on precise temperature control to achieve desired product quality. Customized Insulating Bricks provide reliable thermal insulation in glass furnaces, helping to conserve energy and reduce production costs.

Ceramics and Refractories: In the production of ceramics and refractory materials, maintaining consistent temperatures is essential for achieving desired material properties. Customized Insulating Bricks offer excellent thermal stability and insulation, ensuring uniform heating and cooling throughout the production process.

Incineration and Waste Management: Facilities involved in waste management and incineration require durable thermal insulation solutions to withstand high temperatures and harsh operating conditions. Customized Insulating Bricks provide reliable protection for incinerators, kilns, and other equipment, ensuring safe and efficient waste disposal processes.

By investing in Customized Insulating Bricks from WAM, businesses can experience a range of benefits, including:

Improved Energy Efficiency: By minimizing heat loss and optimizing thermal performance, Customized Insulating Bricks help businesses reduce energy consumption and lower operating costs.

Enhanced Process Reliability: The superior thermal insulation properties of Customized Insulating Bricks ensure consistent temperature control, leading to more reliable and efficient production processes.

Extended Equipment Lifespan: By reducing thermal stress on equipment and machinery, Customized Insulating Bricks can prolong their lifespan and minimize the need for costly repairs and maintenance.

Assessment of Thermal Requirements: Begin by assessing your specific thermal requirements and performance objectives. Consider factors such as operating temperatures, heat transfer rates, and environmental conditions to determine the optimal insulation properties needed for your application.

Consultation with Experts: Seek guidance from experts in the field of insulation materials and thermal engineering. Collaborate with experienced professionals who can provide valuable insights and recommendations tailored to your unique requirements.

Material Selection: Choose the appropriate insulation material based on your application's thermal requirements and performance criteria. Options may include ceramic fiber, refractory bricks, or insulating fire bricks, each offering distinct properties and benefits.

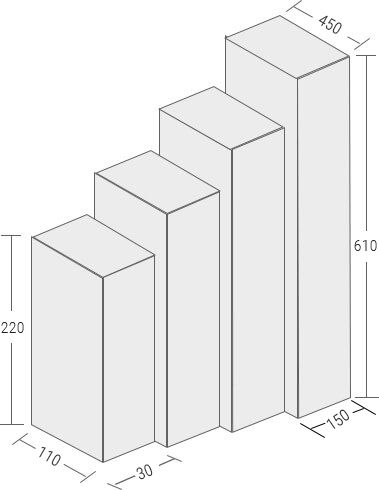

Customization Options: Explore customization options available for insulating bricks, such as size, shape, density, and thermal conductivity. Work closely with manufacturers to tailor the specifications of the insulation bricks to match your exact requirements.

Testing and Validation: Prior to full-scale production, conduct testing and validation of customized insulation bricks to ensure they meet performance standards and specifications. Evaluate factors such as thermal conductivity, heat resistance, and durability through rigorous testing protocols.

Installation and Integration: Once customized insulation bricks have been manufactured and validated, proceed with installation and integration into your application. Follow recommended installation practices to ensure proper alignment, sealing, and thermal insulation performance.

Monitoring and Maintenance: Implement a monitoring and maintenance program to regularly assess the performance of customized insulation bricks and identify any potential issues or degradation over time. Address maintenance needs promptly to ensure continued efficiency and longevity.

Continuous Improvement: Continuously evaluate the performance of customized insulation bricks and seek opportunities for improvement. Incorporate feedback from operational experience and technological advancements to refine and optimize insulation solutions for enhanced efficiency and effectiveness.

By following these steps, you can effectively customize insulation bricks to meet your thermal needs and maximize efficiency in your industrial processes. With tailored solutions designed to optimize thermal management, customized insulating bricks offer a cost-effective and sustainable solution for achieving superior performance and energy savings in various applications.

In conclusion, Customized Insulating Bricks offer tailored solutions for businesses seeking to maximize efficiency and optimize thermal performance in high-temperature environments. With their superior insulation properties and versatility, these bricks are essential components of any industrial operation looking to achieve sustainable growth and competitiveness. Choose Customized Insulating Bricks from WAM and unlock the full potential of your thermal management strategies.