The Best Solution For Your Specific Needs

The Best Solution For Your Specific Needs

Tel: +86-532-85717690/85717352/85832089

Tel: +86-532-85717690/85717352/85832089 E-mail: wam@wamcn.net

E-mail: wam@wamcn.net

Refractory materials like insulating bricks have historically been used extensively for the lining of metallurgical structures used in the manufacturing of crude steel.

Even though their primary function was once essentially restricted to safeguarding the steel vessel casings, they now need to be seen as an essential component of the metallurgical process.

The advancement of both iron and steel production technologies occurred concurrently with the innovation of refractory technologies and insulating materials.

But the main characteristic of insulating bricks is appropriately characterized as the capacity to confine compounds at extreme temps.

Also, they are made up of a broad category of materials that exhibit this property to varied degrees over time and depending on the operation.

Insulating bricks come in a wide range, are produced in a range of shapes and configurations, and have been modified for use in numerous applications.

When in use, they are typically exposed to temperatures more than 1000°F (538°C).

The energy-saving brick used in steel manufacturing ought to be lightweight, non-corrosive, and have excellent insulating qualities.

The development of the lightweight insulation fire brick aims to lower volume density, enhance resistance to thermal shock, increase mechanical strength, lessen linear change during the reheating process, enhance insulation performance, increase service life, and be more cost-effective.

However, note that It is very difficult to improve the bricks for a furnace's working surface when the temperature is above 1500 degrees Celsius.

Refractory materials are used in the iron and steel industries to stop liquid metal from oxidizing and creating slag.

Zirconium oxide(ZrO2), alumina (Al2O3), silicon oxide(SiO2), and magnesia (MgO) make up the majority of these refractories

These are widely used in the iron and steel industries because of their exceptionally high melting point, cost-effectiveness, great resistance to thermal shock, and simple installation.

They also have strong chemical tolerance and corrosion resistance as well. However, these refractories are useless in situations involving high temperatures.

Alumina-based refractoriness is extensively used in the iron and stainless steel industries.

Due to their higher melting point, minimal heat conduction, and excellent corrosion resistance, refractory materials made from alumina are widely used in the metallurgical industry.

Refractoriness based on magnesia is utilized in the production of high-carbon irons and steel.

The high insulating properties and its exceptional resistance to oxidation and corrosion of magnesium-based bricks serve as its defining characteristics.

The use of zirconia-based refractory materials is widespread in the iron, steel, and non-ferrous metals industries like copper(Cu), Zinc(Zn).

Zirconia-based refractories provide remarkable mechanical strength, durability at extreme temps, and superior resistance to corrosion.

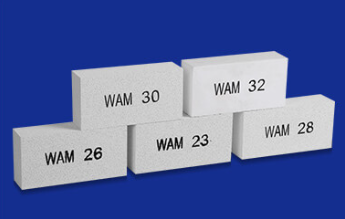

For applications necessitating a thermal material that is abrasion-resistant, our company exclusively supplies durable insulating bricks.

The insulating brick is one of our best-selling products. Please don't be reluctant to reach us for further details if you have any queries about this exquisite line of refractory goods or are unfamiliar with their applications and uses.